Prototypes

The challenge in prototype tooling is clearly defined: be precise, be fast and be inexpensive! Furthermore the results must be close as possible to the later original. The solution: Rapid Tooling.

With our standard mould base systems and hot runner systems, we use cutting-edge HSC technology to manufactures inserts and aluminium mould plates. With an optimized process chain up to the plastic injection process, we create the necessary conditions to produce up to 1,000 prototypes parts in the original material in a short time. We manufacture individual components or complete assemblies and create test reports on request.

You can find more information in our plastic injection molding section.

The advantages of the Sauer-Puzzle-Tooling for prototypes

- Delivery of first parts possible in 2 weeks!

- Rapid Tooling – fast engineering of mould & tools for moulded parts in the original material, in quantities of 1 and more.

- Easy creation of complex geometries

- Inexpensive mould inserts and mould plates - thanks to Sauer & Sohn's own mould base systems and various hot runner systems

- Near-series gating possible

- Possibility of multiple parts in one tool

- Tempering of mold plates and cavities

- Rapid and inexpensive modification of the mould

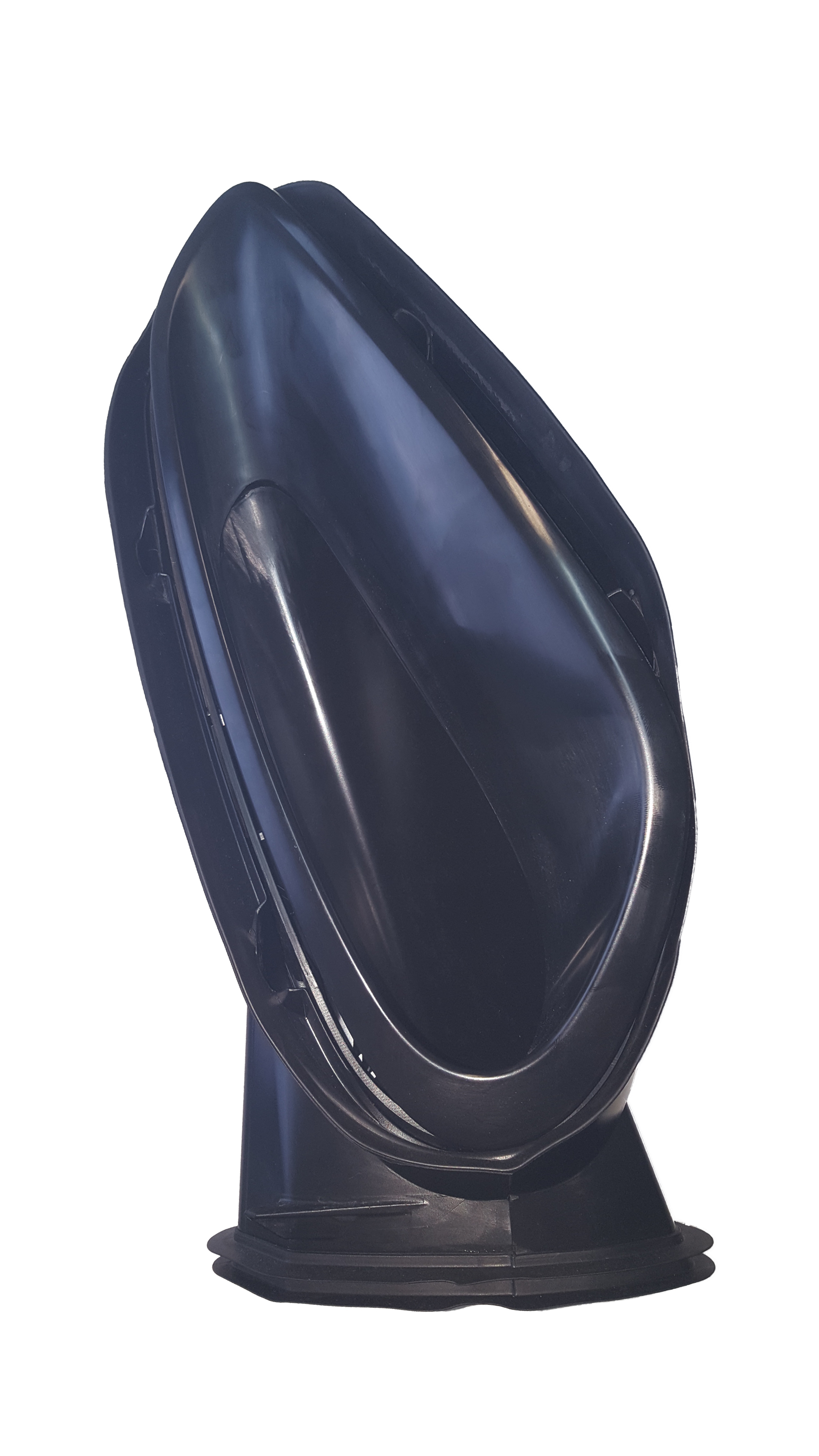

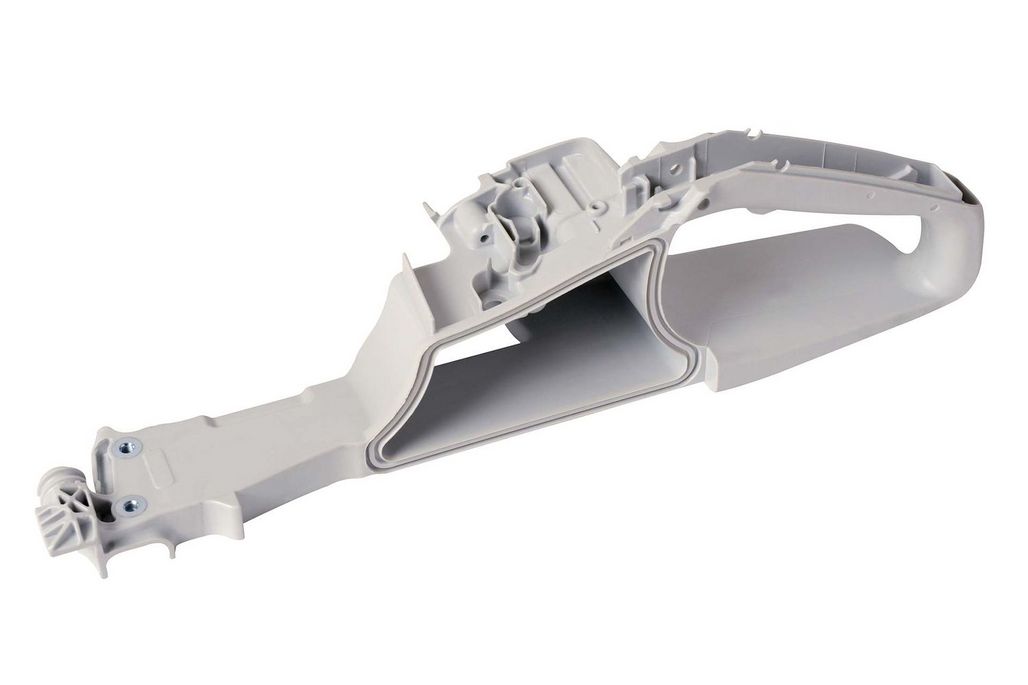

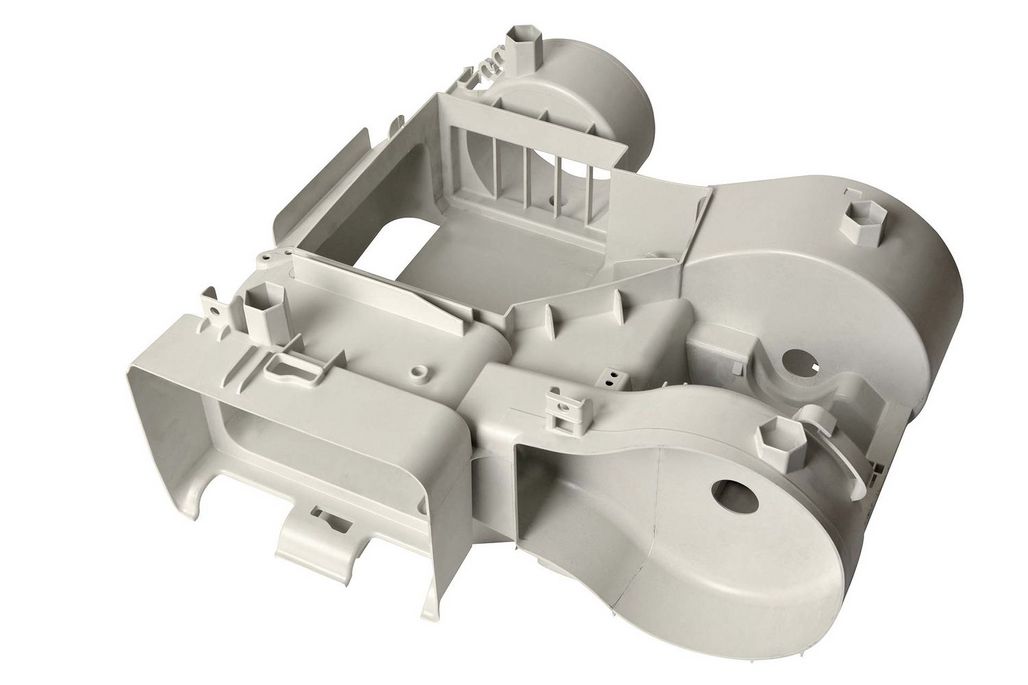

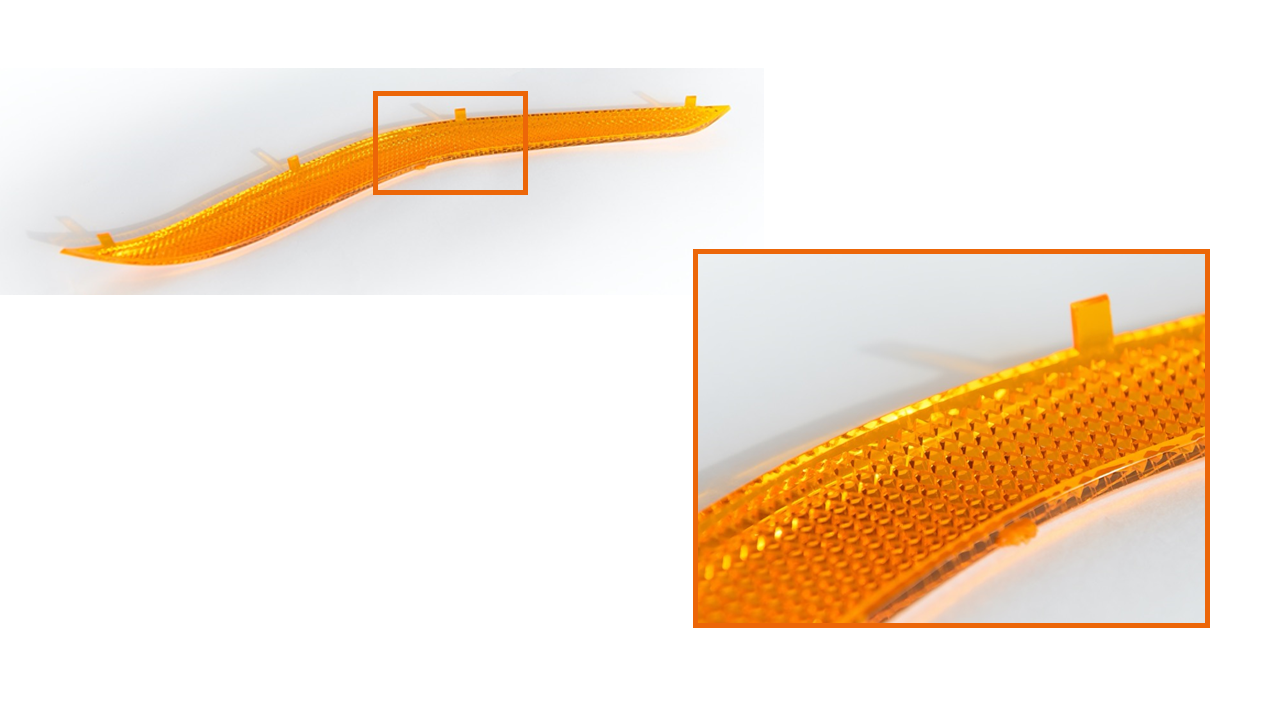

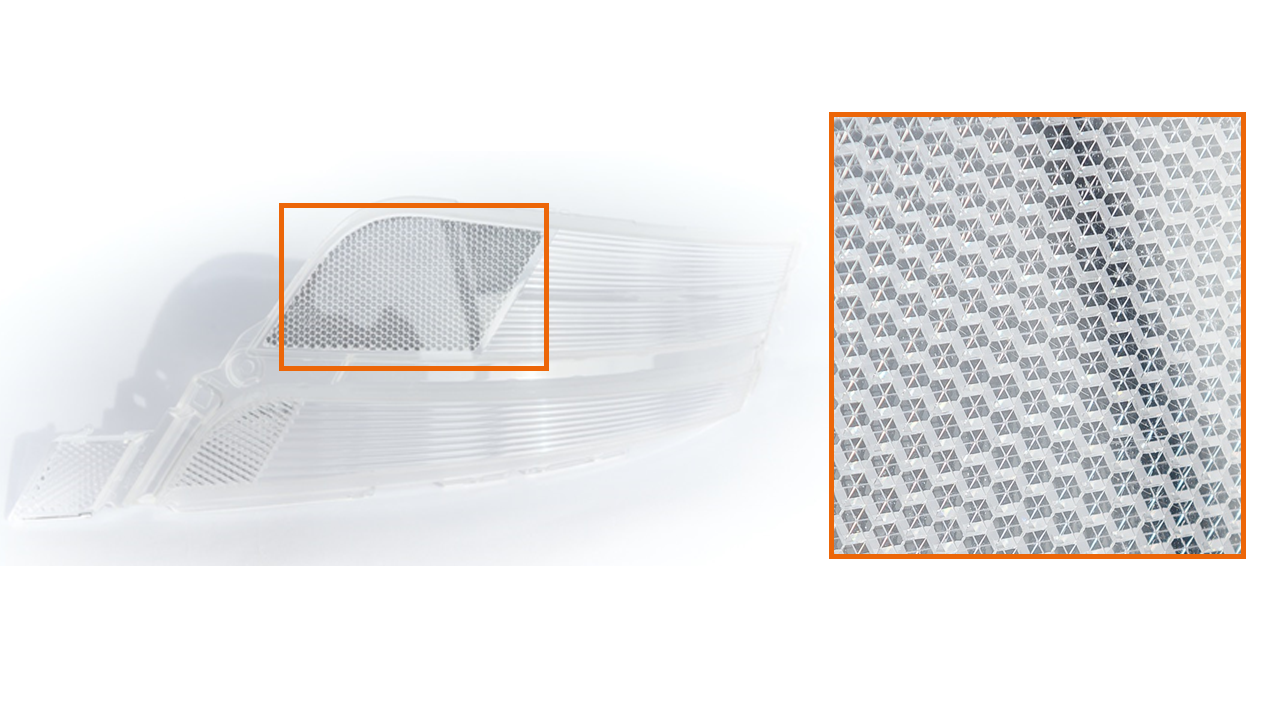

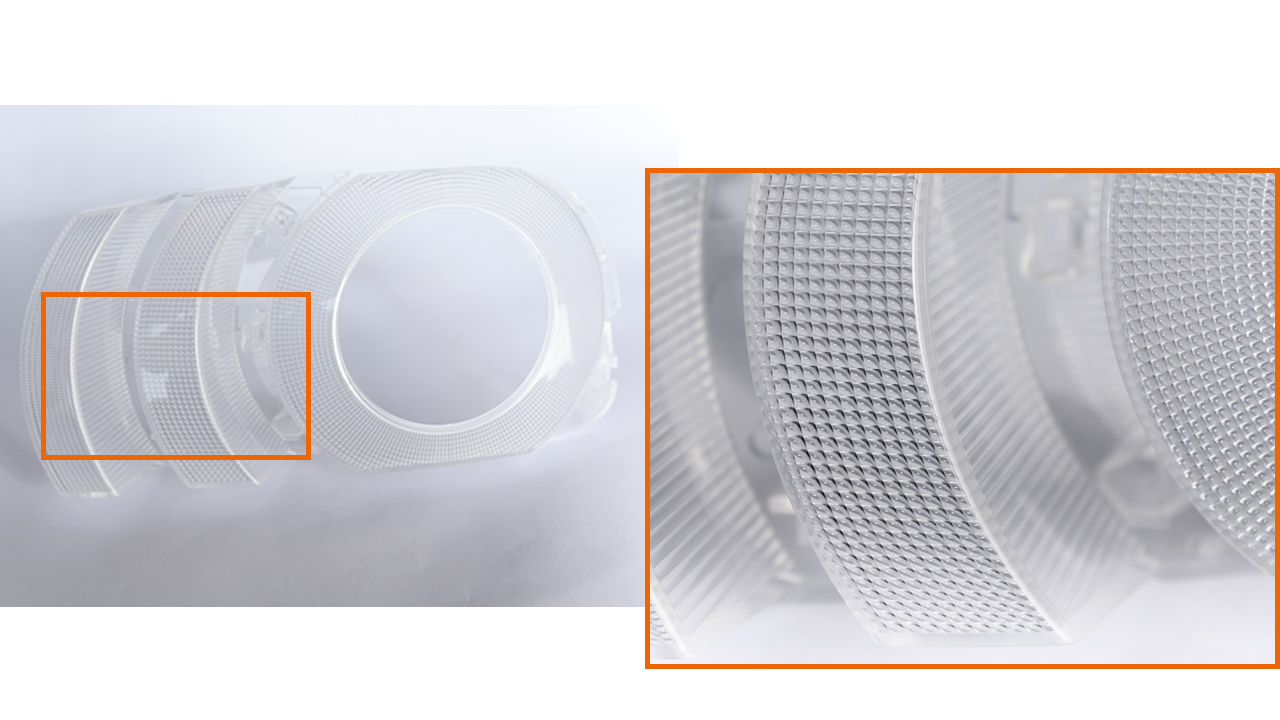

Product examples

- Motor- und Säulenabdeckung

- 2K-Luftführungselemente

- Lighting

- Luftklappensteuerung

- Tankverschlußsysteme

- Frontgrill

- Gehäuse & Verbindungsstücke

- Axial- & Radiallüfter

Your contact persons

Wolfgang Höfling

Head of Rapid Tooling

Telefon: +49 6071 206 120

w.hoefling(at)sauerundsohn.de

Holger Lambracht

Head of Design Department

Telefon: +49 6071 206 135

h.lambracht(at)sauerundsohn.de